Midlothian Energy - Power Plant Reconstruction

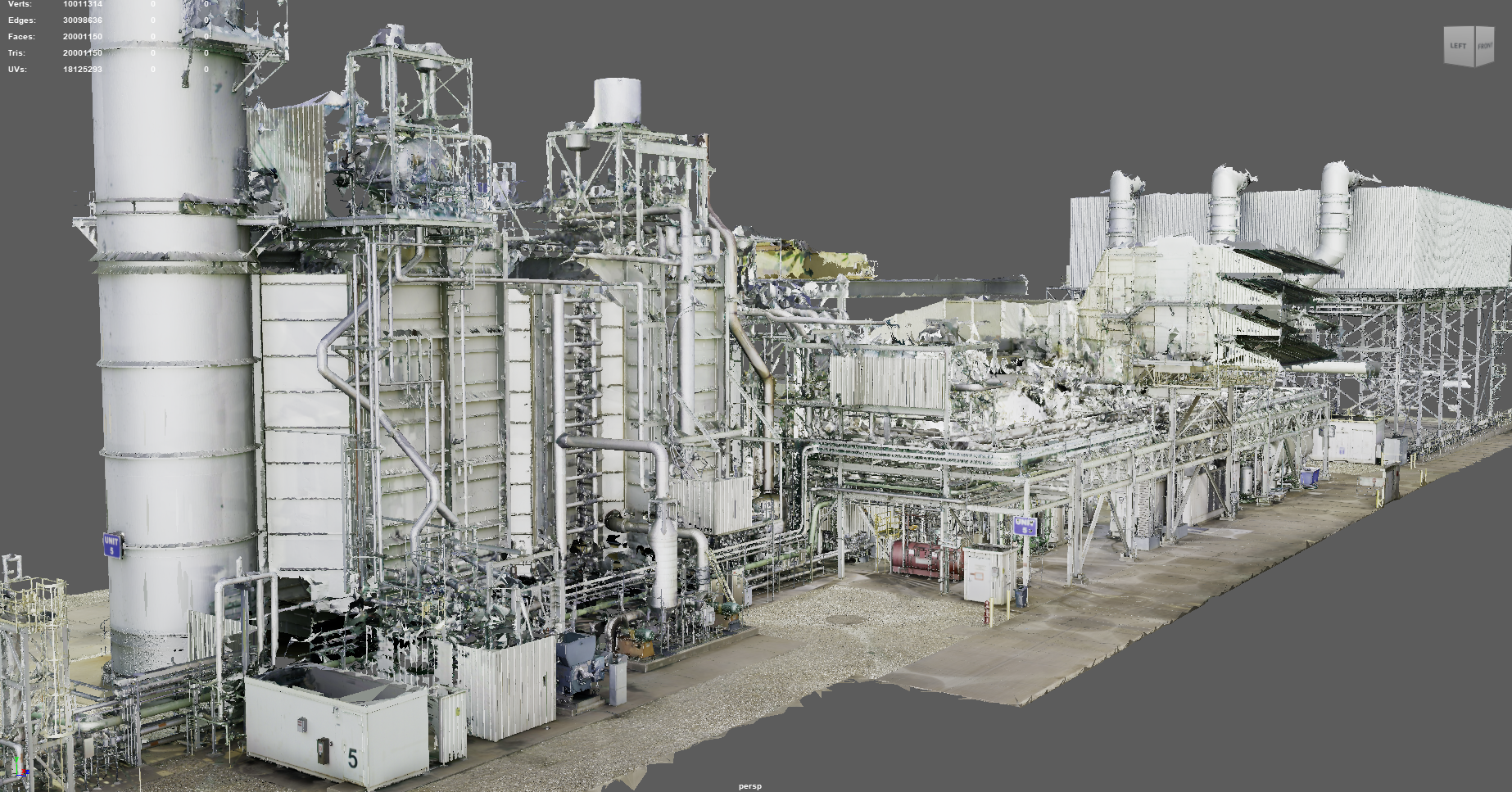

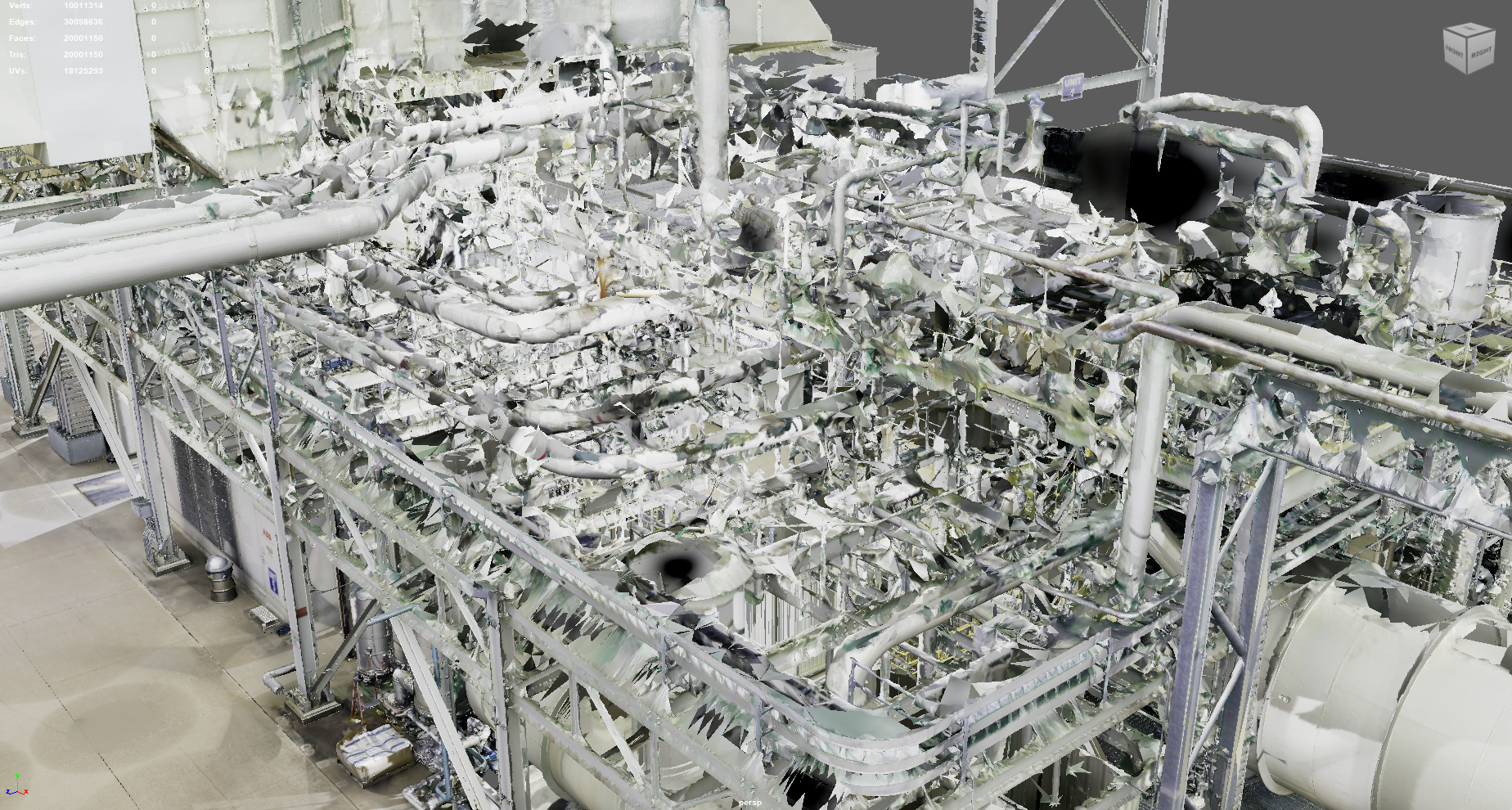

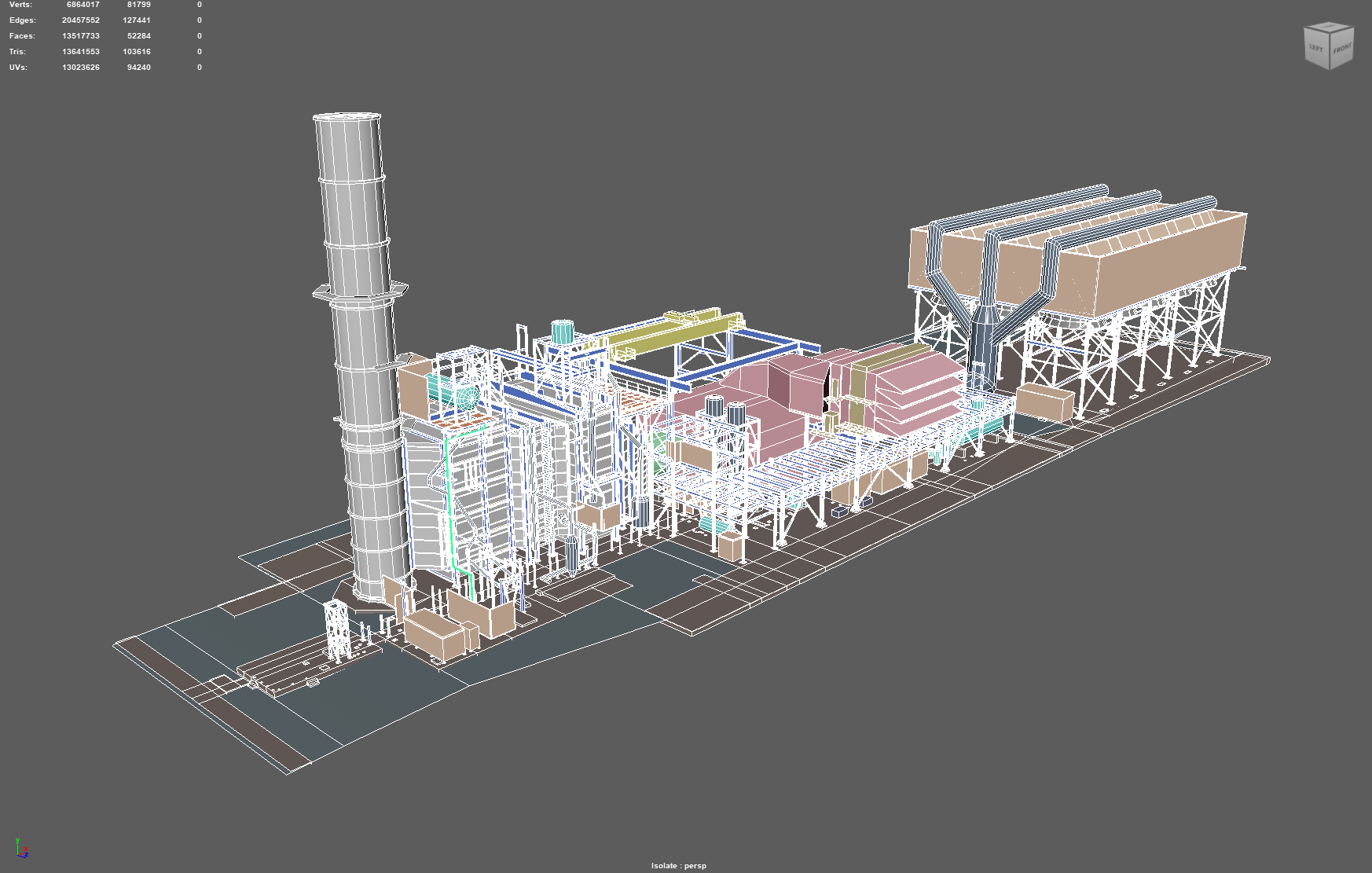

The provided FARO scan point cloud data was a 20 million triangle mesh the client intended to use in a VR walkthrough experience.

The client intended to reduce the triangle count via retopology in order to ensure the model could run efficiently on VR headsets, which require significantly reduced polygon counts due to limited processing power.

Unfortunately, point cloud scans tend to be very “noisy” and often generate artifacts when the scanner’s view of the subject is obstructed. The resulting mesh is highly irregular, lacking distinct and continuous edge flow along objects in the scene. As a result, automated retopology algorithms are unable to accurately determine surface boundaries or maintain geometric integrity, making manual reconstruction the only viable solution.

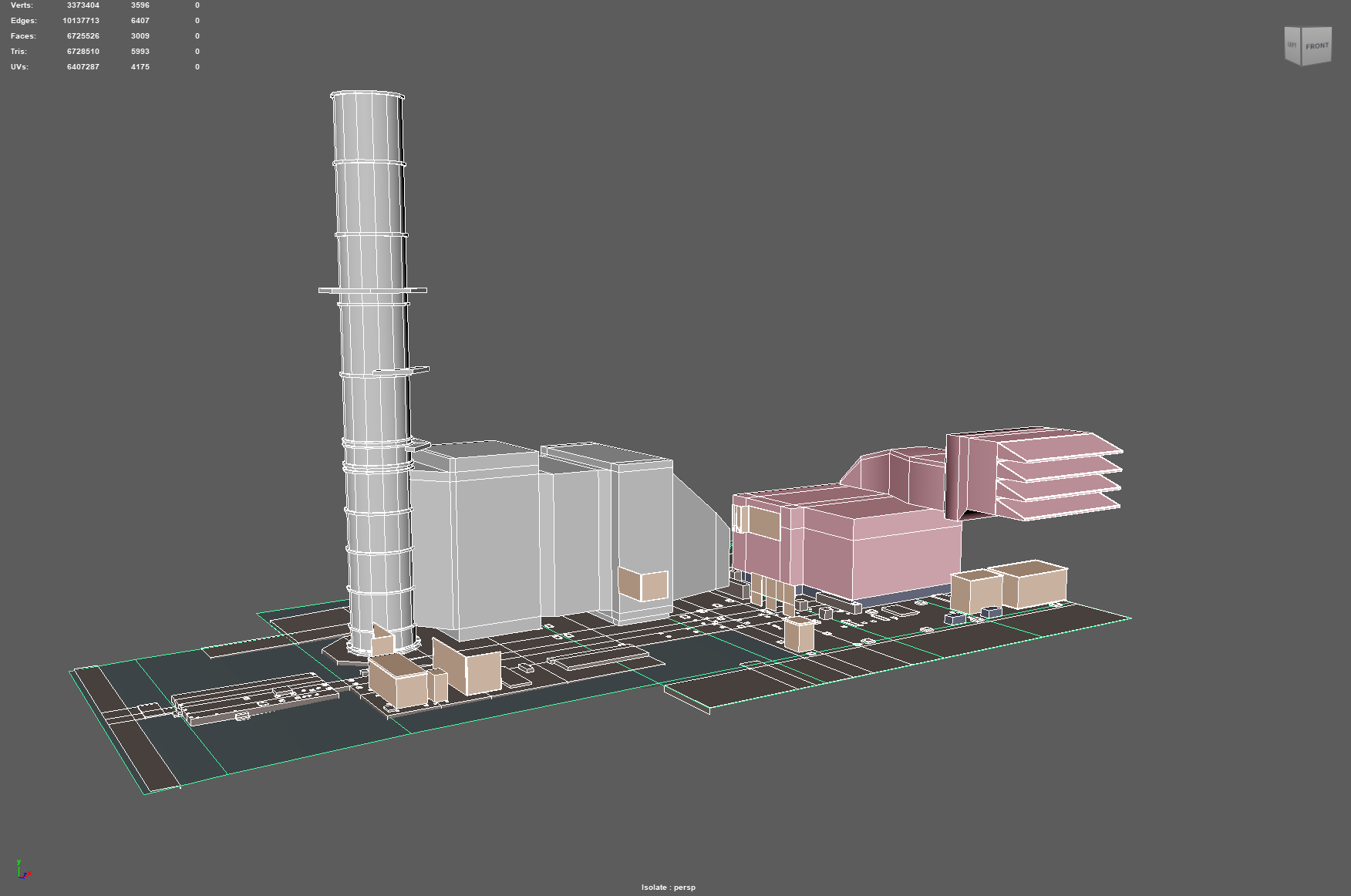

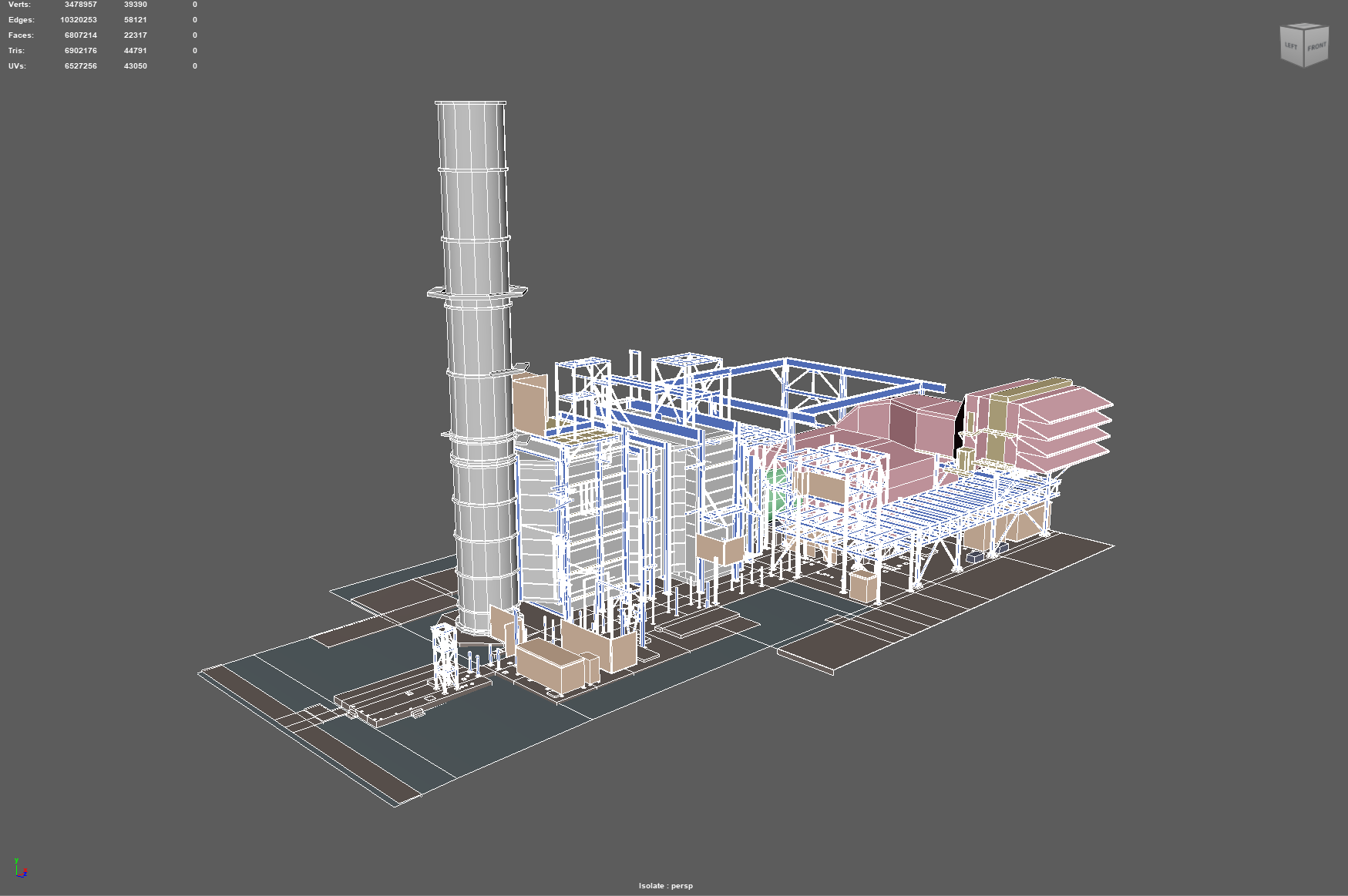

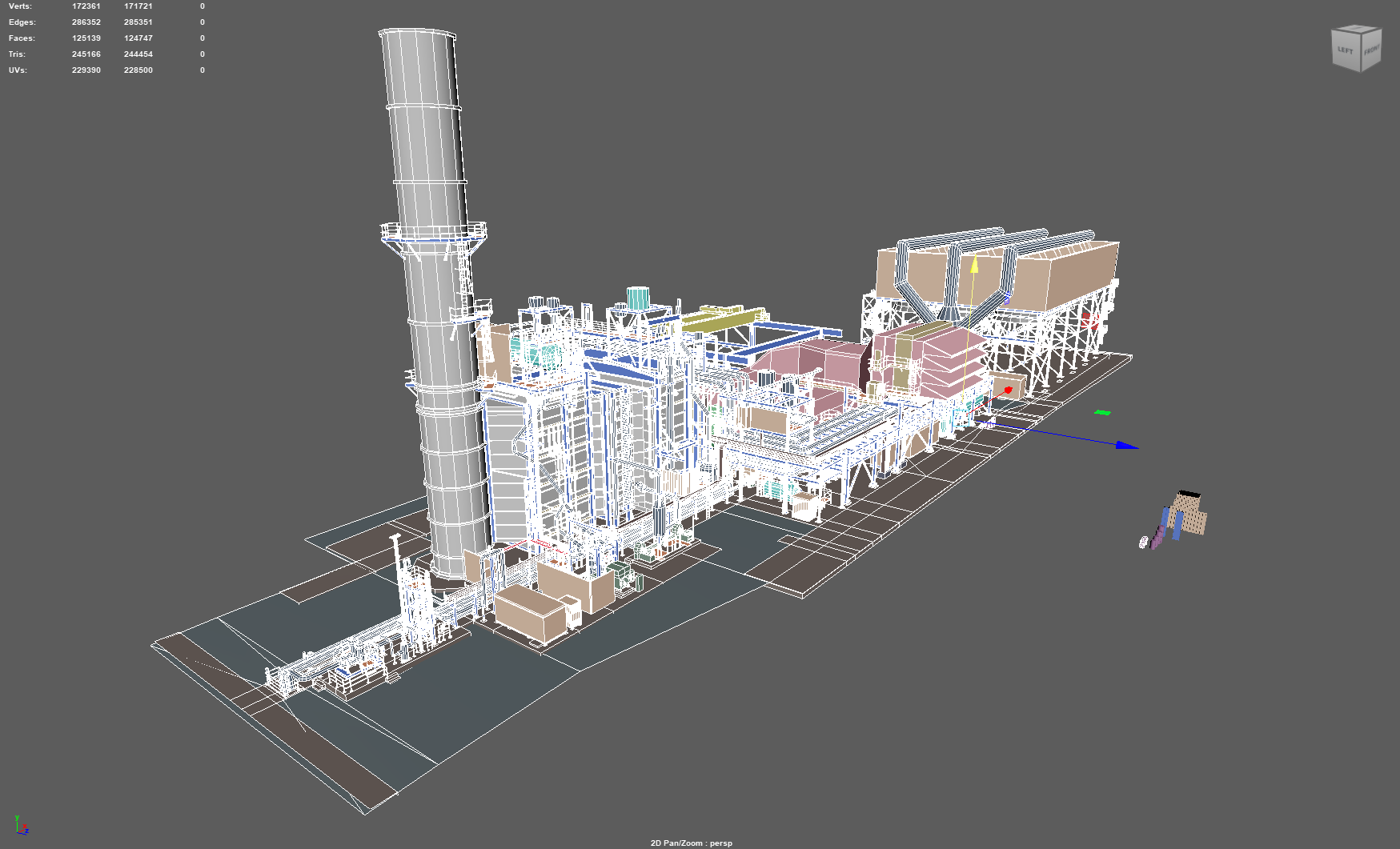

Over the course of a month, we reconstructed the power plant from the ground up using the point cloud data, on-site photography, plant design documents, and aerial imagery from Google Maps. The rebuild followed industry best practices to achieve the lowest possible polygon count while preserving high visual fidelity and structural accuracy.

After modeling, analogous structures were merged into mesh groups to enhance performance via occlusion culling in-engine.

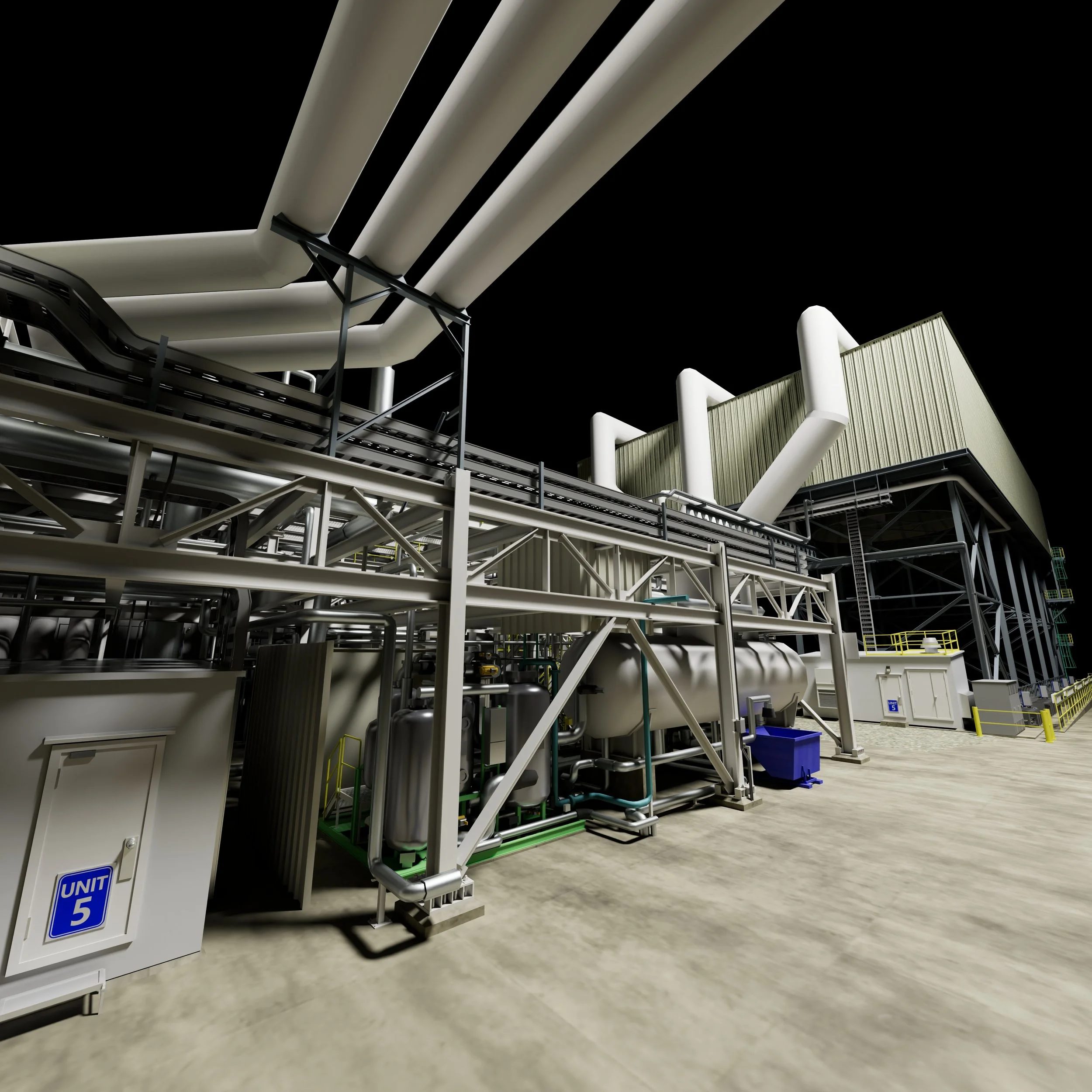

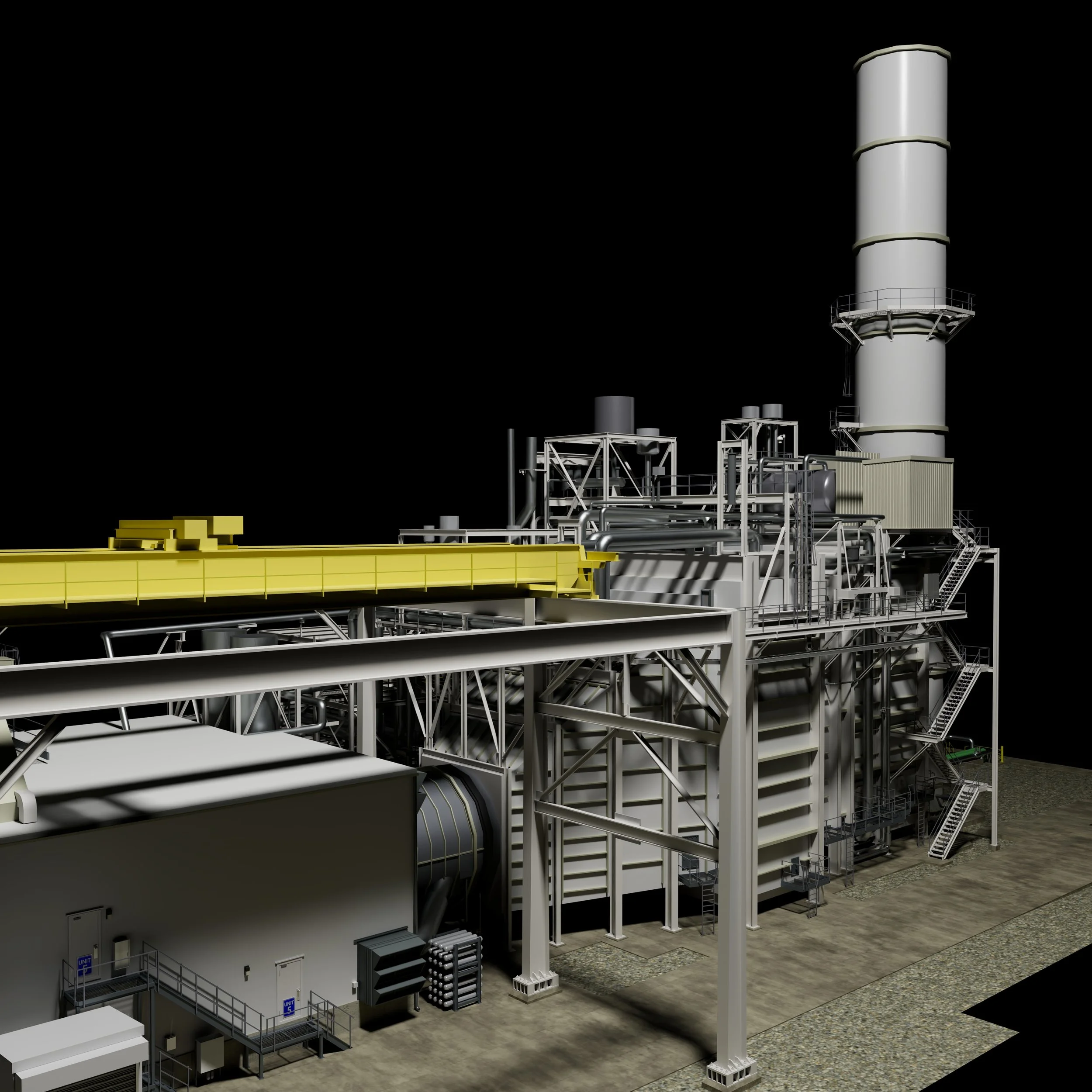

A single packed 4K texture was utilized for the entire model. Eighty-one unique materials were identified within the scene and efficiently organized across a shared UV layout. Because multiple materials overlapped across different meshes, it was not possible to bake certain texture maps such as ambient occlusion, position, or curvature.

For testing purposes, the model and textures were imported into Unity, utilizing the Universal Render Pipeline (URP) Lit shader for its optimized performance in VR environments.

Finally, the model and textures were reimported into Maya and the resulting renders were made using the Arnold renderer.